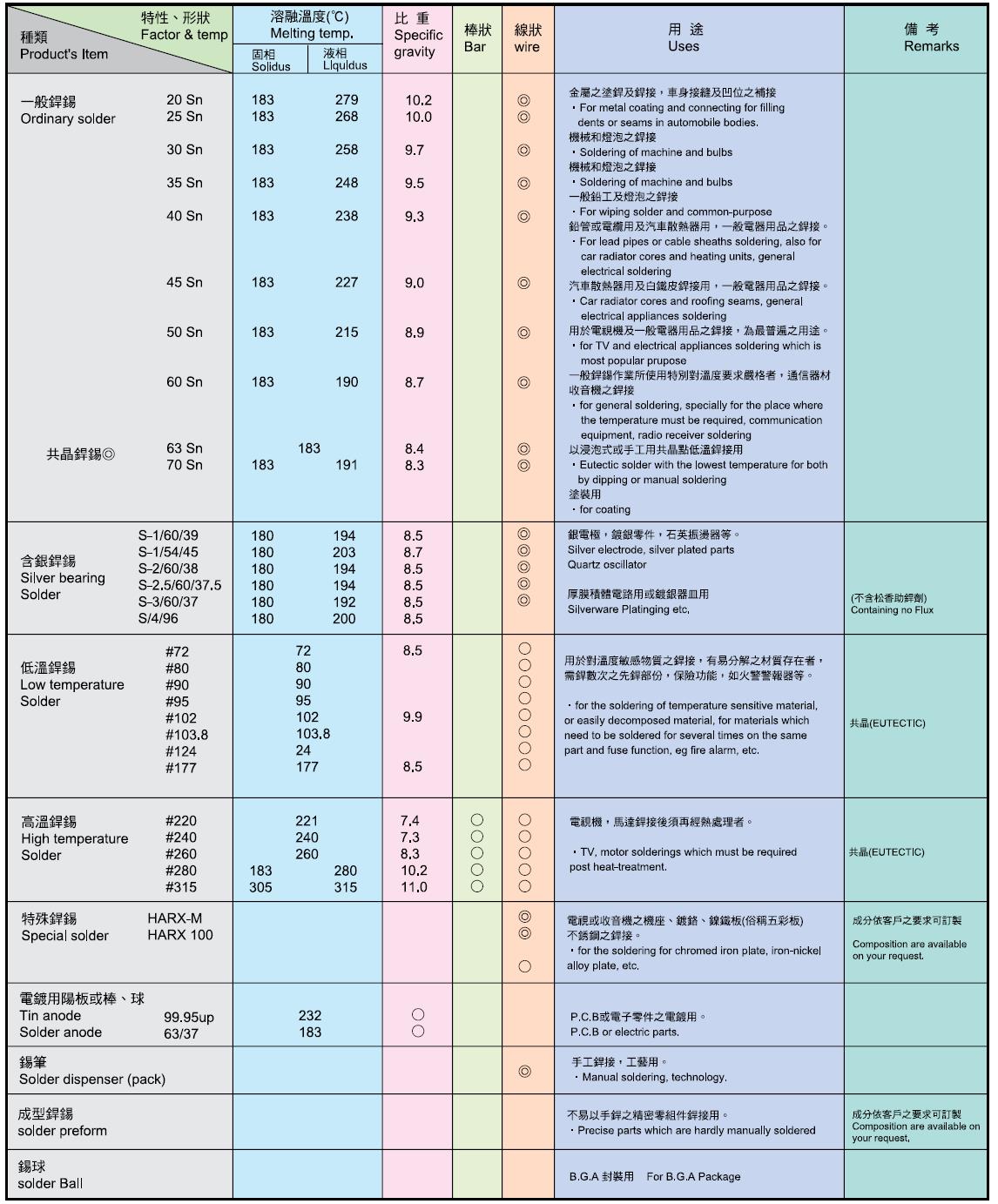

■ SnPb產品之種類規格及用途

◆ 產品之種類規格及用途 / 可製成樹脂心之焊錫絲者 Table and Solder From Guide List / Available flux cored solder.

■ ※其他另有多種規格歡迎洽詢Other solder alloys are available on your request.

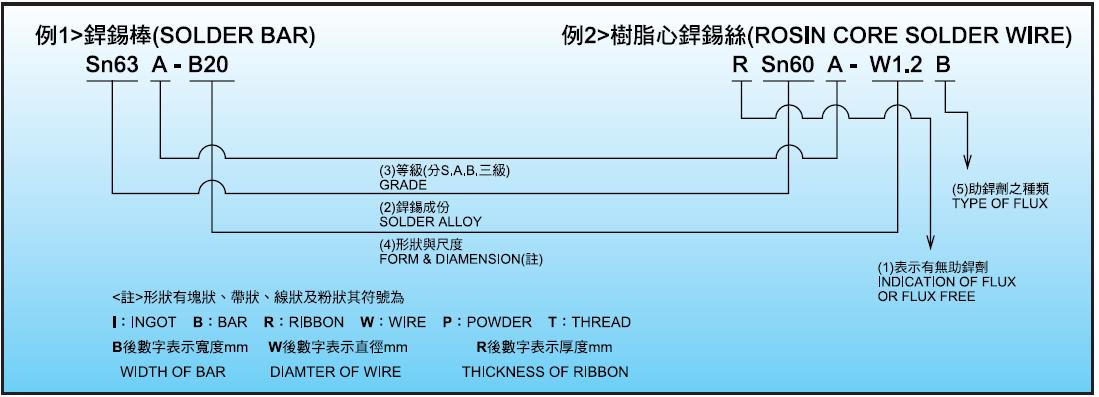

◆ 產品之標示: Indication System of Solder

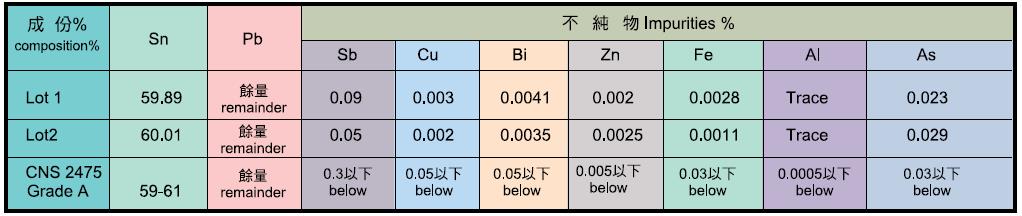

■ 產品之等級:Grade(符合中國國家標準CNS 2475)

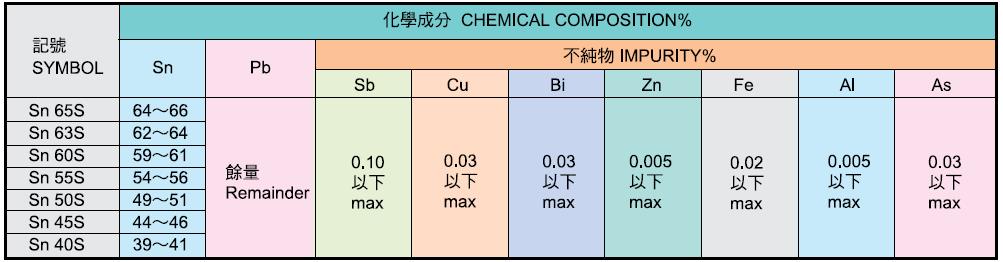

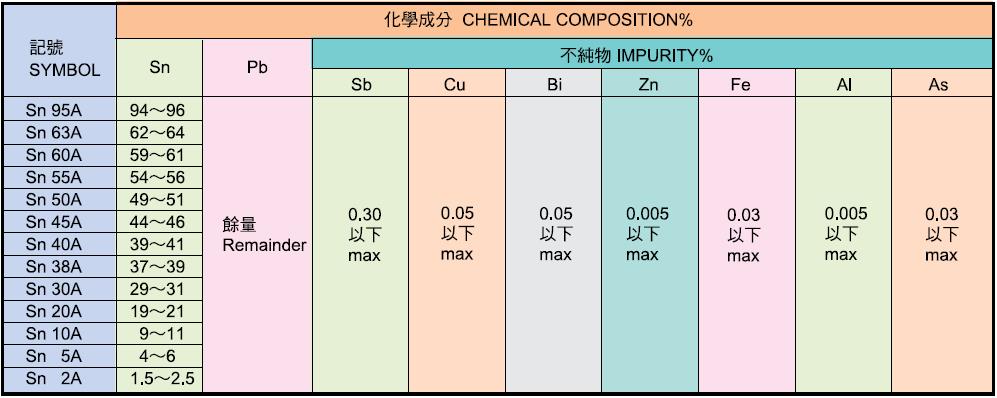

◆ 焊錫S級之化學成分 Class S chemical composition

◆ 焊錫A級之化學成分Class A chemical composition

■ 樹脂心焊錫絲:

◆ 其顯著特點: 1具有適度活性化,使任何形態的焊接均可適應。 2.不腐蝕,不起臭味。 3.焊接性能最佳。 4.可以迅速完成焊接作業而省時省力。

■ Rosin-core SnPb Solder Wire:

◆ Significant Features 1.With appropriate activity, it adapts to any form of soldering. 2.Non-corrosive, no unpleasant odor. 3.Excellent Wetting. 4.Soldering can be completed rapidly, save time and laborer.

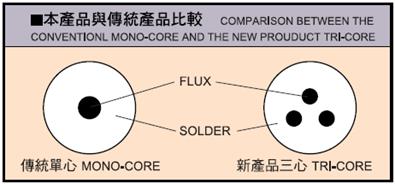

■ 三心樹脂焊錫絲: 以往國內生產的樹脂心焊錫絲只能做出單心的, 原因不外乎技術上的困難和設備的簡陋,單心的樹脂心焊錫絲,因為樹脂焊劑都集中在一處,以烙鐵頭等加熱時候很容易,因突然受熱而使焊劑或焊錫粒到處噴,因此有人在焊錫絲上割v型溝,使焊劑露出空中,讓加熱時氣體能逸去空中以免噴散,更有人使用焊錫粉與焊劑粘合成型為線狀以達其目的。這工作方法雖好,但也有其缺點: (1)焊劑露岀會粘手 (2)不能久放 (3)價格昂貴等...。 三心的焊錫絲使焊劑平均分散三處,受熱時焊劑之熱膨脹及產生之氣體壓力,亦因分散而大大的減少了噴散情形;更因三心焊錫絲作業性能之改良而縮短了作業時間。 樹脂心焊錫絲的最大課題是焊接性能、有無空心、可靠性及作業時臭味之發生和使用時之噴散。 新原新型三心樹脂焊錫絲係針對解決上述問題而新開發之產品,因為它的性能優良,尤其適用於精密配件之焊接或自動焊接。

◆ Tri-core Solder Wire: Currently, the resin flux-cored solder manufactured in the countiy is mono-flux. This is mainly due to the lack ward of technology and equipment. The resin solder flux of lhe mono-flux is gathered at a point, when heat is applied, the flux spattered, As a result, a v-shaped slot is made an the surface of the solder wire, in order to expose the solder flux, thus the air may be released. Others maker use of solder powder and solders flux to form a wire solder. Although this is a good method, it still has its disadvantages as the below: (1) the exposed solder flux will stick to hand, (2) cannot be deq) for a long period, (3) expensive. Tri-core solder wire distributes the flux uniformly, the gas evolved during heating is thus greatly reduced. Further, the working condition for the tri-core solder is greatly improved, thus the tune for operation is also reduced. The most important characteristics of resin flux, solder are on wetting, hollow flux, reliability in, the odor release at work and spattering when it has been soldered. The aforementioned new product is developed in order to solve the problems. Due to its excellent properties, it is especially suitable for precision parts soldering or automatic soldering.

◆ 特點

● 三心之焊錫絲。 ● 不起臭味。 ● 焊劑及焊錫粒噴散殆無。 ● 擴散性特佳,適用於大量生產,並減低不良率。 ● 焊劑之殘渣非常穩定,長期放置也不致有腐蝕或降低絕緣性。

◆ FEATURES

● Tri-core solder wire. ● Generates little odor during soldering. ● No spattering to flux or solder particle. ● Excellent spreadability, suitable for mass production which also decrease defect occurring ratio. ● Residue of flux is stable, no corrosion occurred for long period storage or decrease insulativity.

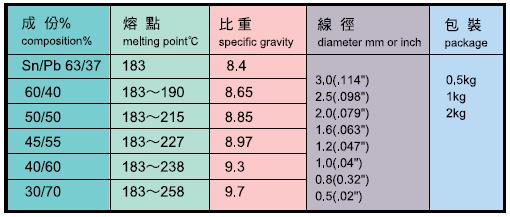

■ 種類及包裝 Kinds and Packing

Sn any composition, Dia 0.3S mm -3.0 mm can be manufactured. 錫可以任何比例成份,線徑0.38 mm -3.0 mm皆可生產。

■ Non-Corrosive If the residue after soldering possesses corrosivity, it will affects the quality of electrical appliances. The test carried out an SPARKLE SOLDER proves that there is no corrosion occurred. On the contrary, it protects the covered portion from oxidation (due to external influence) on the soldered area.

■ Sparkle Solder Typical Products & Specification

Sn any composition, Dia 0.3S mm -3.0 mm can be manufactured. 錫可以任何比例成份,線徑0.38 mm -3.0 mm皆可生產。

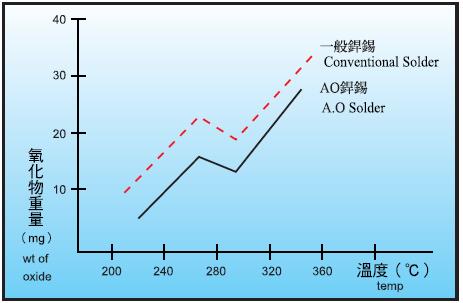

■ 抗氧化焊錫棒

◆ 減少一半錫渣 本公司之除氧焊錫棒係以特殊方式處理將一般焊錫中之氧化物 (即錫渣)除去,當焊錫熔融時氧化物之發生量較一般焊錫減少了將近一半,且焊錫表面能保持較久時間,對於作業上之改善及產品品質之改良均有良好之效果。

◆ AO solder bar Our AO solder bar has been undergone special treatment. It removed the oxide of the solder (dross). While the solder is melted, the occurring of the oxides is less than half of the conventional solder , moreover, the serface of the solder can be kept clean for a long period which can greatly improve the working condition and the quality of product.

◆ 特性 1.熔解後氧化物(錫渣)之發生量較一般焊錫減低近半。 2.焊錫之流動性較佳,焊錫性能較好,減少無謂之浪費。 3.本產品具氧化防止作用,無需添加油臘類之氧化防止劑。 4.符合CNS正字標記之規定及JIS、ASTM等之規格。

◆ Special Feature 1.The occurring of oxide (dross) after melting is less than common solder (about reducing 50%). 2.The flowing property of solder, wetting property is better and minimizes the loss of solder during soldering. 3.This products possesses anti-oxidizing agent to be added. 4. Meet the requirement CNS、及JIS、ASTM standard specification.

抗氧焊錫之防止氧化作用,以靜止式焊錫爐為顯著。下圖係將抗氧焊錫與一般焊錫氧化物(錫渣)發生量作比較。

The effect of anti-oxidation AO solder bar is more signification in dip soldering. The below chart shows the generation oxide between AO solder and general solder.

■ 抗氧焊錫棒化學成份之二例 Chemical composition of AO solder bar

■ SnPb表面黏著用焊錫膏 Solder Paste for SMT

■ SMT錫膏 Sparkle Paste OZ 從不可能完成可能,球型粒與具優異化學安定性的助焊劑調製而成。Sparkle Paste OZ可以提供對一般焊錫合金更長的儲藏期及範圍更加寬廣的選擇。如特殊合金成份、顆粒大小、助焊劑種類、熔點,以滿足特殊需求。

■ SMT Paste The Sparkle Paste OZ sense takes the 〝im〞out of〝impossible〞. The sense also provides significantly longer shelf lives for ordinary solder alloy pastes and a wide range of products to satisfy your particular alloy composition, grain size, flux type, and melting temperature need. Good printability and excellent dispensability makes a high quality reflow soldering.

〝oxide zero〞OZ uniformed spheres 〝oxide zero〞OZ均一的球狀

One white line in the photo is 100 um 照片中一條白線代表100 um

After Print (printed condition in 50 times) Fine printing without 〝slumping〞keep excellent resolution.

After Reflow (after 24 hours) Excellent stability & very few remaining solder ball.